How Cutting-Edge 3D Scanning Is Transforming Architectural Design

Enhancing Manufacturing Processes: The Impact of 3D Laser Scanning on High Quality Control

3D laser scanning innovation is changing high quality control in production. By supplying exact dimensions and high-resolution information, it enables producers to identify variances from specs easily. This innovation not only streamlines inspection procedures yet also enhances functional performance. 3D Scanning. The application of this technology comes with its own collection of difficulties. Discovering these elements discloses the wider implications for industries and the future landscape of production

Recognizing 3D Laser Scanning Technology

Although 3D laser scanning innovation has progressed considerably recently, its essential concept continues to be straightforward: catching the exact geometry of things using laser beams. This innovation utilizes laser light to gauge ranges in between the scanner and numerous factors on a things's surface area. The information accumulated is after that refined to develop a thorough 3D version, precisely showing the measurements and contours of the scanned object.

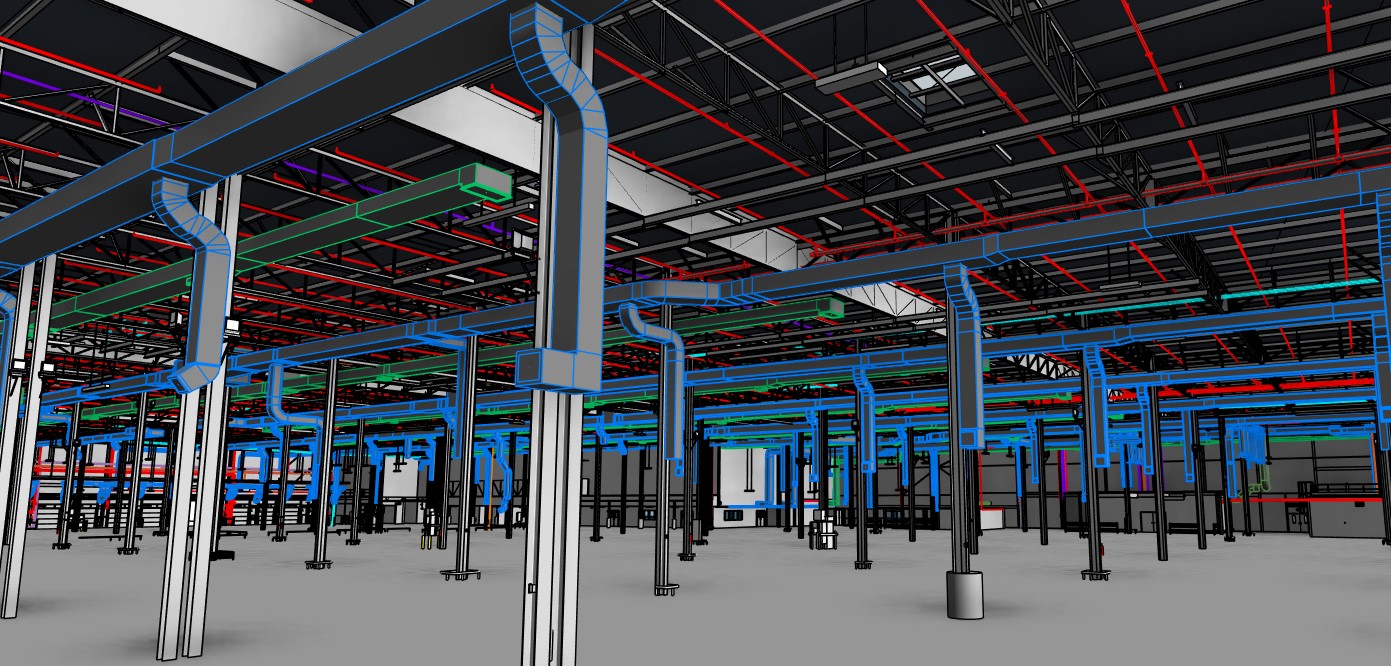

Commonly, 3D laser scanners can be classified right into 2 primary types: contact and non-contact scanners. Contact scanners literally touch the things to collect dimensions, whereas non-contact scanners utilize laser beam of lights to capture data from a range. The convenience of this modern technology allows its application throughout different industries, including building and construction, manufacturing, and architecture. Its ability to produce high-resolution versions assists in high quality control, reverse engineering, and quick prototyping, eventually enhancing layout accuracy and performance in manufacturing processes.

Advantages of 3D Laser Scanning in Manufacturing

As manufacturers seek to improve performance and precision in their processes, the advantages of 3D laser scanning have come to be progressively apparent. This cutting-edge innovation allows for extremely accurate and fast measurements of complicated geometries, considerably minimizing the time needed for quality checks. By recording in-depth data, suppliers can determine disparities early in the production procedure, thus decreasing waste and revamp expenses.

Furthermore, 3D laser scanning promotes far better style recognition, enabling engineers to contrast as-built problems with original specs. This capacity guarantees that any type of deviations are quickly resolved, enhancing overall product high quality. Additionally, the technology supports the production of digital twins, which can be made use of for simulations and process optimizations. As a result, makers not just raise their functional performance but also improve their competitive advantage out there. On the whole, the assimilation of 3D laser scanning stands for a transformative step towards accomplishing greater requirements in making top quality control.

Assimilation of 3D Laser Scanning Into Quality Assurance

Incorporating 3D laser scanning right into top quality control procedures enhances the accuracy and effectiveness of assessments throughout production. This innovation allows makers to catch in-depth, high-resolution data of components and assemblies, enabling exact dimensions and comparisons against layout requirements. By utilizing 3D laser scanning, organizations can identify discrepancies from tolerances better, which is vital for maintaining item stability.

Real-World Applications and Study

Real-world applications of 3D laser scanning in manufacturing show its transformative influence throughout numerous markets. Aerospace companies use this modern technology to carry out accurate evaluations of components, guaranteeing they satisfy strict safety requirements. A significant situation involved a leading airplane maker that employed 3D laser scanning to streamline its quality assurance processes, significantly decreasing inspection times and mistakes.

In the vehicle sector, suppliers have actually implemented laser scanning to develop digital doubles of their automobiles, allowing real-time adjustments throughout production. One automotive company reported a 30% reduction in rework prices after integrating this modern technology into their setting up lines.

Furthermore, in the durable goods sector, business are using 3D laser scanning for fast prototyping, enabling for quicker iterations and improved item styles. These applications illustrate just how 3D laser scanning not only enhances precision however additionally improves performance and development throughout multiple manufacturing domain names.

Conquering Obstacles in Application

Executing 3D laser scanning in producing presents several difficulties that companies need to browse to completely realize its benefits. One significant obstacle is the preliminary cost of devices and software program, which can deter companies from adopting this innovation. In addition, incorporating 3D laser scanning into existing workflows needs getting rid of resistance to change among workers, demanding comprehensive training programs to ensure efficiency. Information administration additionally postures an obstacle, as the high quantity of details created by 3D scanning have to be effectively processed and evaluated to derive actionable insights. Furthermore, compatibility issues with legacy systems may hinder seamless assimilation, requiring possible upgrades or alterations. Resolving these obstacles is crucial for suppliers intending to improve high quality control and enhance production processes. By developing clear approaches for training, financial investment, and information administration, companies can mitigate these barriers and launch the transformative capacity of 3D laser scanning in their operations.

Future Trends in 3D Laser Scanning for Production

As producing remains to develop, the integration of 3D laser scanning with increased automation is anticipated to transform production procedures. Improved data analytics will certainly play an essential duty in boosting and optimizing operations top quality control. These patterns highlight the potential for greater performance and precision in producing settings.

Boosted Automation Assimilation

The integration of automation in manufacturing has been gradual, the future of 3D laser scanning is poised to accelerate this trend considerably. As producing processes end up being progressively intricate, the need for precise, real-time measurements expands. 3D laser scanning technology offers automated data capture, decreasing labor costs and minimizing human error. This integration permits suppliers to simplify quality control procedures, enabling rapid detection of deviations in production. In addition, the placement of 3D laser scanning with robotics and automated systems promotes smooth operations, enhancing overall performance. As makers embrace these sophisticated technologies, they can expect better precision and efficiency, positioning themselves competitively in a rapidly advancing market. The harmony between automation and 3D laser scanning notes a substantial leap forward in making advancement.

Enhanced Information Analytics

The combination of automation has led the way for developments in information analytics within the domain of 3D laser scanning. Suppliers are progressively leveraging advanced formulas and artificial intelligence strategies to examine vast datasets created by laser scans. This enhanced information analytics capability enables real-time monitoring of making processes, making it possible for the identification of issues and discrepancies more successfully than traditional techniques. Anticipating analytics can visualize possible issues, substantially decreasing downtime and boosting overall effectiveness. Furthermore, the capability to envision data in three measurements gives deeper insights right into manufacturing workflows, promoting far better decision-making. As 3D laser scanning technology remains to advance, the role of information analytics will become progressively critical in driving technology and maintaining affordable benefit in production.

Often Asked Questions

What Industries Benefit one of the most From 3D Laser Scanning?

The sectors that benefit most from 3D laser scanning consist of manufacturing, building, aerospace, vehicle, and health care. These markets use the innovation for precision measurements, quality control, and reliable layout procedures, considerably boosting total functional effectiveness.

How Does 3D Laser Scanning Contrast to Typical Dimension Methods?

3D laser scanning offers greater precision and rate compared to traditional dimension techniques. It captures thorough geometries promptly, decreasing human mistake and helping with better evaluation, which eventually enhances total high quality control in various sectors.

What Is the Expense of Implementing 3D Laser Scanning Modern Technology?

The expense of implementing 3D laser scanning innovation varies significantly, generally varying from $10,000 to $100,000, depending upon software, training, and tools. Organizations must website consider these expenses versus potential effectiveness and quality enhancements.

Exist Particular Software Program Requirements for 3D Laser Scanning?

Yes, 3D laser scanning needs details software application, consisting of data handling and modeling applications. Common options incorporate CAD software, factor cloud processing tools, and specialized applications that promote the integration and analysis of checked information for optimal outcomes.

How much time Does a Common 3D Laser Scanning Refine Take?

A regular 3D laser scanning process can take anywhere from a few mins to numerous hours, relying on elements like the dimension of the object, intricacy of the setting, and required level of detail for accuracy.

3D laser scanning innovation is transforming high quality control in production. 3D laser scanning modern technology has developed significantly in current years, its basic concept remains straightforward: catching the exact geometry of items utilizing laser beam of lights. Incorporating 3D laser scanning right into high quality control procedures improves the precision and effectiveness of assessments throughout production (3D Scanning). 3D laser scanning modern technology uses automated information capture, minimizing labor prices and minimizing human error. The price of executing 3D laser scanning modern technology differs considerably, normally varying from $10,000 to $100,000, depending on software, tools, and training